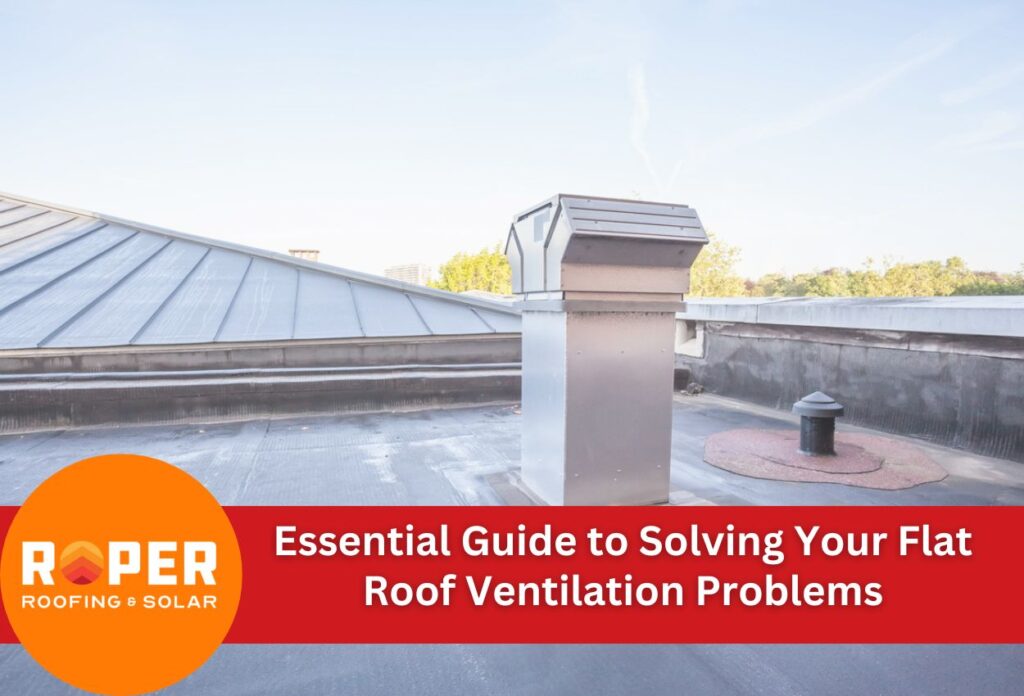

Essential Guide to Solving Your Flat Roof Ventilation Problems

Poor ventilation transforms flat roofs from protective barriers into sources of expensive problems. When air cannot circulate properly through flat roof systems, moisture becomes trapped, creating the perfect environment for mold growth, structural damage, and skyrocketing energy costs. Property owners across commercial and residential buildings face these flat roof airflow problems daily, often without realizing the root cause of their issues.

Flat roof ventilation solutions address these critical concerns by establishing proper air circulation that prevents moisture accumulation and maintains building integrity. Unlike pitched roofs that naturally encourage airflow, flat roof ventilation systems require strategic planning and specialized equipment to move stagnant air effectively. The consequences of inadequate ventilation extend beyond immediate comfort issues, leading to premature roof deterioration and expensive repairs.

Certain warning signs indicate when buildings need improved flat roof ventilation systems. Condensation on interior surfaces, musty odors, unusually high energy bills, and visible moisture damage signal that current ventilation fails to meet building needs. Commercial roof ventilation can be challenging due to larger spaces and complex HVAC systems, while residential flat roofs face similar airflow restrictions, though on smaller scales.

Understanding why flat roof moisture control is important helps property owners identify problems early and implement effective roof ventilation strategies before issues become major expenses.

How Poor Ventilation Destroys Flat Roofs and Buildings

Inadequate ventilation creates a destructive cycle within flat roof systems that begins with trapped moisture and ends with significant structural damage. When warm, humid air becomes trapped beneath roofing materials, it condenses against cooler surfaces, creating persistent moisture problems that traditional flat roof drainage cannot address. This moisture accumulation provides ideal conditions for mold and mildew growth, which gradually weakens roof decking, insulation, and structural components.

The science behind flat roof airflow problems reveals why these systems are particularly vulnerable to ventilation issues. Unlike sloped roofs that naturally channel air movement, flat surfaces create stagnant air pockets where humidity concentrates. Without flat roof ventilation systems, this trapped air undergoes continuous heating and cooling cycles that produce condensation. Over time, this process deteriorates roofing materials from the inside out, leading to premature replacement needs.

Energy efficiency suffers dramatically when flat roof ventilation is inadequate. Buildings with poor commercial roof ventilation experience increased air conditioning usage as trapped hot air radiates heat downward into occupied spaces. HVAC systems work harder to maintain comfortable temperatures, resulting in higher utility bills and accelerated equipment wear. Effective flat roof moisture control through proper roof ventilation installation reduces energy usage while protecting building integrity and extending the roof’s lifespan.

Types of Flat Roof Ventilation Systems That Actually Work

Effective flat roof ventilation solutions fall into two primary categories that address different building needs and energy considerations. Mechanical ventilation systems actively remove stagnant air through powered equipment, while natural ventilation relies on environmental forces to create consistent airflow. Understanding the strengths of each approach helps property owners select appropriate flat roof ventilation systems for their specific situation.

Mechanical ventilation options include exhaust fans and turbine ventilators that actively pull air from problem areas. These systems excel in buildings where natural airflow is insufficient or where precise flat roof moisture control is needed. Exhaust fans installed at strategic roof locations create negative pressure that draws humid air outward, preventing condensation buildup. Powered vents equipped with thermostats automatically activate when temperatures exceed preset levels, ensuring consistent air movement during peak heat conditions.

Natural ventilation solutions harness wind and thermal currents to move air without electricity costs. Box or pop vents positioned on the roof allow hot air to escape naturally, while vents at the roof edges provide intake points for cooler outside air. This creates continuous air circulation that addresses flat roof airflow problems through passive means. Commercial roof ventilation often combines both approaches, using natural systems for baseline airflow and mechanical backup during extreme weather conditions. Proper roof ventilation installation requires balancing intake and exhaust capacity to optimize system performance.

Choosing the Right Ventilation Solution for Your Property

Selecting flat roof vents requires evaluating several building characteristics that directly impact system performance. Building size determines the volume of air that ventilation systems must move, while the existing roof structure influences installation options and equipment placement. Properties with larger square footage need more powerful flat roof ventilation systems or multiple units to achieve adequate air exchange rates throughout the entire space.

Local climate conditions significantly affect ventilation system selection and operation requirements. Areas with high humidity levels need more aggressive flat roof moisture control strategies, while regions experiencing extreme temperature fluctuations benefit from mechanical systems with automatic controls. Wind patterns around buildings influence the effectiveness of natural ventilation, making site-specific assessments essential for optimal roof ventilation installation.

Structural limitations often dictate which commercial roof ventilation options are feasible for specific properties. Older buildings may have weight restrictions that prevent heavy mechanical equipment installation, while newer constructions can accommodate comprehensive ventilation solutions. Existing HVAC systems, electrical capacity, and roof membrane types also influence equipment compatibility and installation approaches.

Matching ventilation capacity to building requirements involves calculating air exchange rates based on interior volume and occupancy patterns. Adequate systems should replace stagnant air completely within reasonable timeframes while maintaining energy efficiency. Properties with persistent flat roof airflow problems typically require systems capable of moving higher air volumes than standard recommendations suggest, ensuring thorough moisture removal and temperature control.

Professional vs. DIY Ventilation Projects

Professional roofers bring essential expertise to flat roof ventilation installation projects that significantly impact the system’s performance and longevity. Roofing contractors understand the complex relationship between ventilation equipment, roof structure, and building systems that determines installation success. A professional assessment identifies optimal placement locations for intake and exhaust vents based on wind patterns, structural capacity, and existing building systems that property owners typically cannot evaluate accurately.

Additionally, complex flat roof ventilation systems require specialized tools and technical knowledge that most property owners lack. Professional installation ensures all roof pipes are sealed, adequate electrical connections for powered equipment, and compliance with building codes governing commercial roof ventilation. Experienced contractors also recognize potential problems during installation that could lead to leaks, structural damage, or system failures when addressed incorrectly.

Property owners can handle basic maintenance tasks that keep flat roof ventilation solutions operating efficiently between professional service visits. Regular debris removal from vent openings, visual inspection of equipment housing, and cleaning accessible fan blades help maintain airflow capacity. However, any work requiring roof access needs proper safety equipment and fall protection systems.

Electrical repairs, structural modifications, and gaps in the roof should always involve professional roofing contractors. These tasks require specialized knowledge of flat roof moisture control principles and local building codes. Property owners attempting complex roof ventilation installation without proper training risk creating bigger problems than inadequate ventilation, including water damage and structural compromise that leads to expensive repairs.

Special Considerations for Commercial Flat Roof Ventilation

Commercial buildings need specialized approaches to flat roof ventilation compared to standard residential solutions. The massive air volumes within commercial structures need more powerful equipment and strategic placement to achieve effective flat roof moisture control. Large warehouse spaces, office buildings, and retail centers contain significantly more air that must circulate properly to prevent condensation and maintain indoor air quality.

Integration with existing HVAC systems creates additional complexity for commercial roof ventilation projects. Building air handlers, rooftop units, and exhaust systems must work harmoniously with new ventilation equipment to avoid creating negative pressure imbalances or airflow conflicts. A professional assessment can verify that flat roof ventilation solutions complement rather than compete with existing mechanical systems, optimizing overall building performance.

Commercial properties face stringent code compliance requirements that residential buildings typically do not encounter. Energy efficiency standards mandate specific air exchange rates and equipment specifications that must be documented and verified during installation. Commercial roof ventilation systems must meet ASHRAE guidelines, local building codes, and often additional sustainability requirements for LEED certification or similar programs.

Equipment sizing calculations become more critical for commercial applications where inadequate capacity may create expensive operational problems. Professional roof ventilation installation for commercial buildings involves detailed load calculations that account for occupancy levels, heat-generating equipment, and seasonal variations. These calculations ensure that flat roof airflow problems are eliminated without over-sizing equipment that wastes energy and increases operational costs throughout the building’s lifespan.

Maintaining Your Flat Roof Ventilation System for Long-Term Success

Consistent maintenance keeps flat roof ventilation systems operating at peak efficiency throughout seasonal changes and varying weather conditions. Property owners should follow quarterly inspection routines that examine all ventilation components for damage, debris accumulation, and proper operation. These regular assessments spot minor issues before they develop into problems that compromise the entire building.

Cleaning procedures for flat roof vents vary by equipment type but share common principles of debris removal and airflow optimization. Mechanical exhaust fans require periodic cleaning of blades, housing, and motor components to maintain proper air movement capacity. Natural ventilation systems need clear intake and exhaust openings free from leaves, snow, and other obstructions that reduce effectiveness. Professional maintenance ensures that roof ventilation systems receive thorough cleaning that property owners cannot safely perform.

Warning signs of ventilation failure include unusual condensation patterns, persistent odors, and increased energy consumption that signal declining system performance. When flat roof airflow problems resurface after previous solutions, equipment malfunction or capacity limitations are typically responsible. Temperature variations between different building areas often indicate uneven air distribution caused by blocked vents or failing mechanical components.

Preventive measures extend the operational life of roof vents through proactive component replacement and system upgrades. Regular filter changes, motor lubrication, and electrical connection inspections prevent sudden equipment failures that leave buildings vulnerable to moisture damage. A professional evaluation every few years ensures that your flat roof ventilation systems continue meeting building needs as structures age and requirements change.

Optimize Your Property with Flat Roof Ventilation Solutions from Roper Roofing & Solar

Ensuring your flat roof has proper ventilation is not just about improving airflow; it’s about safeguarding your investment and enhancing the living or working environment beneath it. Roper Roofing & Solar specializes in flat roof ventilation solutions that tackle everything from moisture control to energy efficiency. Whether you’re dealing with condensation issues, mold growth, or high energy costs due to inadequate ventilation, our team has the expertise to diagnose and resolve your specific challenges.

Choosing the right ventilation system involves understanding your building’s size, local climate, and specific airflow needs. At Roper Roofing & Solar, we don’t just install generic systems — we tailor solutions to match your property’s needs, ensuring your roofing system performs optimally throughout its lifespan.

Don’t let poor ventilation compromise the integrity of your building. Call Roper Roofing & Solar today at (720) 475-1065 for a professional assessment and to find the perfect ventilation solution for your flat roof.